PRODUCTS

Products

-

Guardrail Roll Forming Machine

- -

Rack Shelf Roll Forming Machine

- -

Strut Channel Roll Forming Machine

- -

Scaffolding Roll Forming Machine

- -

Customized Roll Forming Machine

- -

Door Frame Roll Forming Machine

- -

Deck Floor Roll Forming Machine

- -

Roof Panel Roll Forming machine

--

Roof Panel roll forming Machine

-

Corrugated Roll Forming Machine

-

Glazed Tile Roll Forming Machine

-

Double Layer Roof Panel Roll Forming Machine

-

PU Roof:Wall Panel Roll Forming Machine

-

Standing Beam Roll Forming Machine

-

Ridge Cap Roll Forming Machine

-

Down Spout Roll Forming Machine

-

Gutter Roll Forming Machine

-

Roof Panel roll forming Machine

-

Cable Tray Roll Forming Machine

- -

CZ Purlin Roll Forming Machine

- -

Vineyard Post Roll Forming Machine

- -

Stud and Track Roll Forming Machine

- -

Roller Shutter Door Roll Forming Machine

- -

Fire Damper Roll Forming Machine

- -

Metal Slitting Line

- -

Cut to Length Line

- -

Tube mill

--

High Frequency Carbon Steel Tube Mill

-

DB25 High-frequency Tube Welding line

-

DB32 Welding Pipe Tube Mill

-

DB50 Carbon Steel Tube Mill Line

-

DB50 Expanded 76 High Frequency Welded Tube Mill Line

-

DB76 Expanded 127 HF Straight Seam Welded Tube Mill Line

-

DB89 Welded Pipe Forming Tube Mill Machine

-

DB114 Welded Carbon Steel Tube Mill

-

DB219 ERW Welded Tube Mill

-

High Frequency Carbon Steel Tube Mill

-

PU Sandwich Panel Line

- -

Auxiliary Machine

-

Product description

Parameters

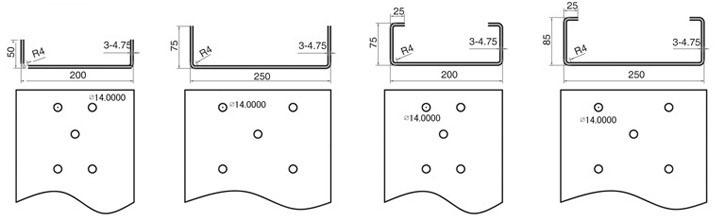

Profile drawings

Optional configuration

Video

Description

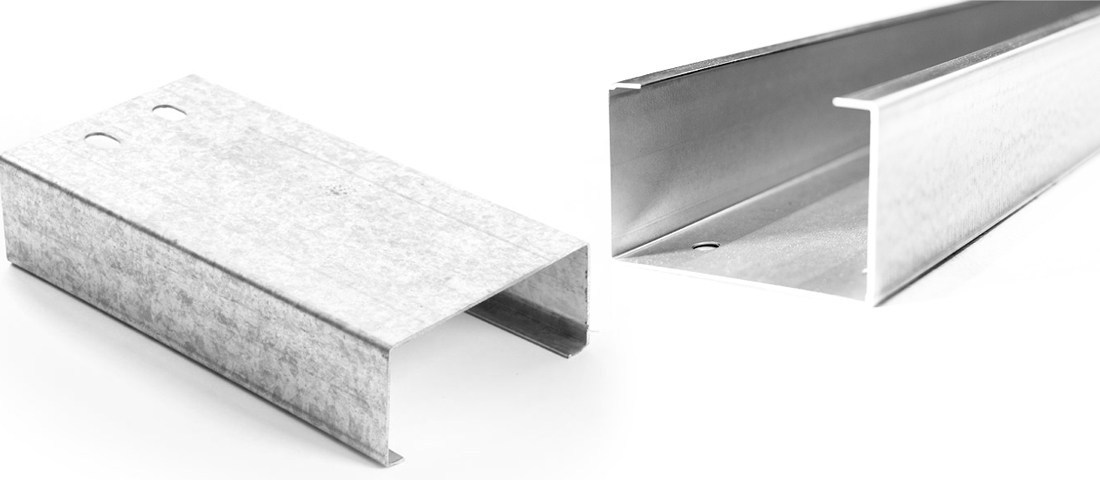

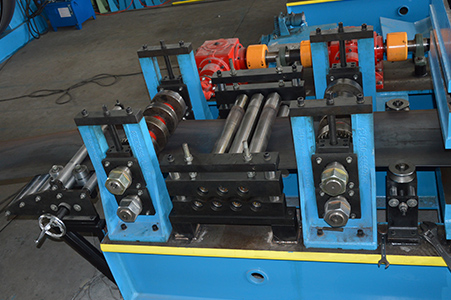

This C/U Purlin Roll Forming Machine is used to produce C shape and U shape purlins from 80-300mm of width, normally its material thickness is 1.5-3mm, also Maximum thickness can be formed at 4.0-6.0mm according to customer requirement.

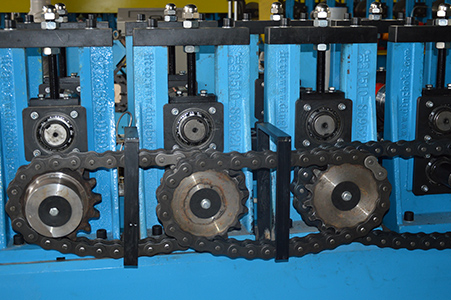

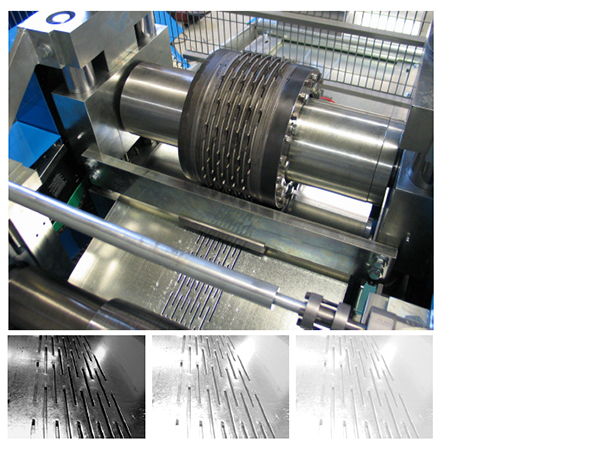

Also we can design this machine to work with any size of the purlin, automatically adjustable sizes by PLC or manually adjust handle wheel to change the sheet width to get different width and height. This is much more easily than adjust the spacers and can save more time. Regarding the punching unit, we can design pre punching unite according to your requirement. For cutting unit, you can choose the pre-cut or post-cut which is universal cutting. The driving system we adopt the gimbal /gearbox for transmission if the raw material is thicker than 2.5mm,this is much more strong driving power and more stable when forming the purlins.

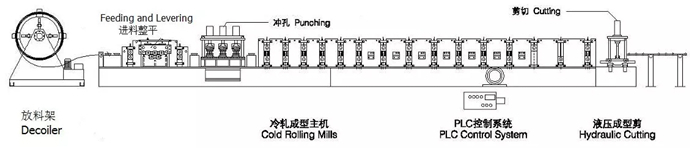

Working Flow

Manual Decoiler -- Feeding&leveling -- Punching -- Roll-forming -- Hydraulic cutting -- Discharge table

Application

|

|

Application

C purlin can be used in the main body stress structure of the large and medium-size enterprises civil construction, like the plant, warehouse, locomotive shed, hangar, exhibition building, theatre, stadiums, roofing load-bearing load and wall surface support of the arbour.

C purlin is usually used for roofs and walls. It is best to use continuous beam structure, because the roof needs to withstand the weight of snow and wind.

Due to the failure of overlap, C purlin can only form a simple support rather than a continuous beam structure. This is why C purlin bar is mainly used for wall purlin and Z purlin for roof purlin.

|

|