PRODUCTS

Products

-

Guardrail Roll Forming Machine

- -

Rack Shelf Roll Forming Machine

- -

Strut Channel Roll Forming Machine

- -

Scaffolding Roll Forming Machine

- -

Customized Roll Forming Machine

- -

Door Frame Roll Forming Machine

- -

Deck Floor Roll Forming Machine

- -

Roof Panel Roll Forming machine

--

Roof Panel roll forming Machine

-

Corrugated Roll Forming Machine

-

Glazed Tile Roll Forming Machine

-

Double Layer Roof Panel Roll Forming Machine

-

PU Roof:Wall Panel Roll Forming Machine

-

Standing Beam Roll Forming Machine

-

Ridge Cap Roll Forming Machine

-

Down Spout Roll Forming Machine

-

Gutter Roll Forming Machine

-

Roof Panel roll forming Machine

-

Cable Tray Roll Forming Machine

- -

CZ Purlin Roll Forming Machine

- -

Vineyard Post Roll Forming Machine

- -

Stud and Track Roll Forming Machine

- -

Roller Shutter Door Roll Forming Machine

- -

Fire Damper Roll Forming Machine

- -

Metal Slitting Line

- -

Cut to Length Line

- -

Tube mill

--

High Frequency Carbon Steel Tube Mill

-

DB25 High-frequency Tube Welding line

-

DB32 Welding Pipe Tube Mill

-

DB50 Carbon Steel Tube Mill Line

-

DB50 Expanded 76 High Frequency Welded Tube Mill Line

-

DB76 Expanded 127 HF Straight Seam Welded Tube Mill Line

-

DB89 Welded Pipe Forming Tube Mill Machine

-

DB114 Welded Carbon Steel Tube Mill

-

DB219 ERW Welded Tube Mill

-

High Frequency Carbon Steel Tube Mill

-

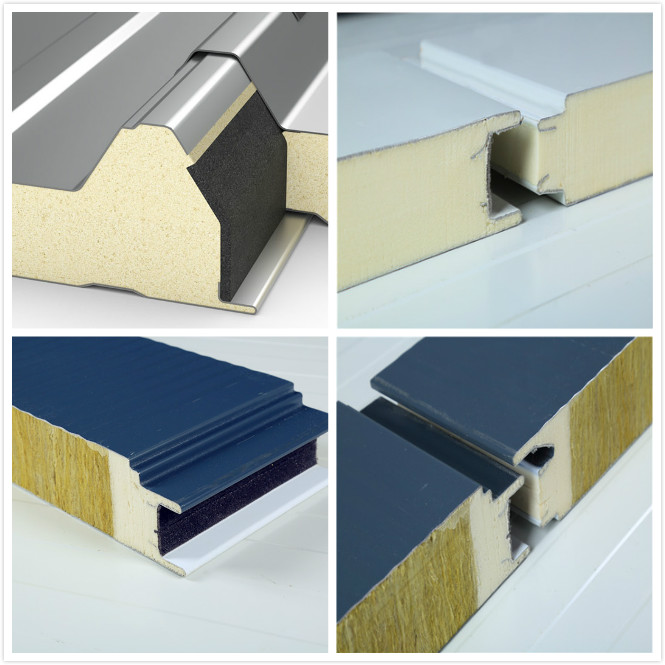

PU Sandwich Panel Line

- -

Auxiliary Machine

-

Product Descriptions

Technical Parameters

|

1. Producing speed |

Min. 0meter/min ~Max. 10meter/min |

|

2. Length of Double belt conveyor |

20~40meter |

|

3. Factory Electricity |

380V x 50Hz x 3Ph (User’s choice available) |

|

4. Controlling Electricity |

A.C. 220V (User’s Choice Available) |

|

5. Factory’s Area |

130~150(Length) x 30m(Width) x 6m(Height) |

|

6. Pressure of compressed air |

Over 6 bar required |

|

7. Production |

4~5 person |

The general specification of PU panel produced

|

1. Panel length |

Min. 2,000mm in auto mode |

|

Max. 18,000mm (±3mm) |

|

|

2. Effective width |

1000mm for roof |

|

600mm~1200mm for normal wall |

|

|

3. Panel thickness |

Available thickness from 30~200mm |

|

(depended upon heights of the side sealing block.) |

|

|

4. Top and Bottom layer |

Pre-painted Galvanized coil |

|

For ASTM A 526-85, JIS G 3302 SGCC |

|

|

Thickness = 0.4mm ~ 0.7mm |

|

|

5. insulation |

PUR hardened and PIR / Pentane |

|

6. Density of Insulation |

30kg/m3 ~ 50kg/m3 |

Application