PRODUCTS

Products

-

Guardrail Roll Forming Machine

- -

Rack Shelf Roll Forming Machine

- -

Strut Channel Roll Forming Machine

- -

Scaffolding Roll Forming Machine

- -

Customized Roll Forming Machine

- -

Door Frame Roll Forming Machine

- -

Deck Floor Roll Forming Machine

- -

Roof Panel Roll Forming machine

--

Roof Panel roll forming Machine

-

Corrugated Roll Forming Machine

-

Glazed Tile Roll Forming Machine

-

Double Layer Roof Panel Roll Forming Machine

-

PU Roof:Wall Panel Roll Forming Machine

-

Standing Beam Roll Forming Machine

-

Ridge Cap Roll Forming Machine

-

Down Spout Roll Forming Machine

-

Gutter Roll Forming Machine

-

Roof Panel roll forming Machine

-

Cable Tray Roll Forming Machine

- -

CZ Purlin Roll Forming Machine

- -

Vineyard Post Roll Forming Machine

- -

Stud and Track Roll Forming Machine

- -

Roller Shutter Door Roll Forming Machine

- -

Fire Damper Roll Forming Machine

- -

Metal Slitting Line

- -

Cut to Length Line

- -

Tube mill

--

High Frequency Carbon Steel Tube Mill

-

DB25 High-frequency Tube Welding line

-

DB32 Welding Pipe Tube Mill

-

DB50 Carbon Steel Tube Mill Line

-

DB50 Expanded 76 High Frequency Welded Tube Mill Line

-

DB76 Expanded 127 HF Straight Seam Welded Tube Mill Line

-

DB89 Welded Pipe Forming Tube Mill Machine

-

DB114 Welded Carbon Steel Tube Mill

-

DB219 ERW Welded Tube Mill

-

High Frequency Carbon Steel Tube Mill

-

PU Sandwich Panel Line

- -

Auxiliary Machine

-

Product description

Parameters

Profile drawings

Optional configuration

Video

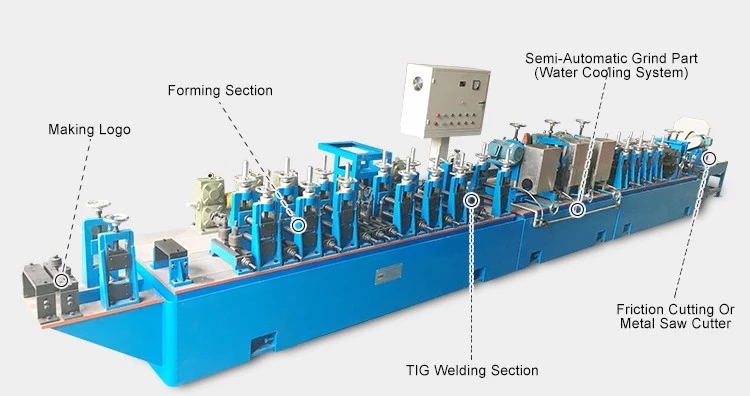

Product Descriptions

The High frequency galvanized square pipe and round pipe welding machine is used to manufacture cold pipe and cold rolled coils into a tube-shaped blank and its subsequent parts to produce Φ20mm-Φ63.5mm circular tube welding with a thickness of 0.5mm-2.0mm Into the tube, edge heating is performed by a solid-state high-frequency welding machine, longitudinal seam welding is performed in the roller of the tube welding machine, cooling, further sizing or shaping, and on-line cutting of the annular pipe according to the measured length. The finished product will be round, square or rectangular pipes.

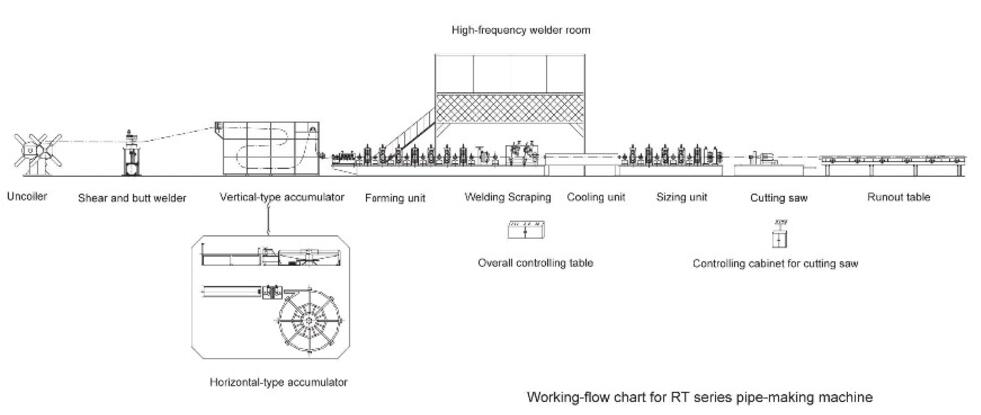

Working Flow

Raw material (strip steel roll) – Material feeding – End cutting and butt welding (hand welding) – Strip storage cage – Material feeding and forming – High frequency welding – Removing outer burr – Cooling water jacket – Fix the diameter and straightening – Cut off with flying saw – Material unloading (Manually stow and bind up) – Inspection – Storehouse

Technical Parameters

Raw material:Carbon steel

Maximum coil weight:≤2500kg

The diameter of the pipe:20-63.5mm (20*20-50*50mm for square pipe)The thickness of the strip steel: 0.5-2.0mm

The length of the pipe: 3-12m

Equipment processing speed: 20-120m/min

Dimension of machine:40M*5M(L*W)

Machine Components

|

Serial No. |

Commodity & Description |

Quantity |

|

1 |

Manual un-coiler |

1 set |

|

2 |

Feeding guiding |

1 set |

|

3 |

Roll forming machine |

1 set |

|

4 |

Cooling system |

1 set |

|

5 |

Straighten device |

1 set |

|

6 |

Miter Saw Cutting |

1 set |

|

7 |

Output table |

1 set |

|

8 |

Controlling system (including cabinet) |

1 set |

Machine pictures

Application