PRODUCTS

Products

-

Guardrail Roll Forming Machine

- -

Rack Shelf Roll Forming Machine

- -

Strut Channel Roll Forming Machine

- -

Scaffolding Roll Forming Machine

- -

Customized Roll Forming Machine

- -

Door Frame Roll Forming Machine

- -

Deck Floor Roll Forming Machine

- -

Roof Panel Roll Forming machine

--

Roof Panel roll forming Machine

-

Corrugated Roll Forming Machine

-

Glazed Tile Roll Forming Machine

-

Double Layer Roof Panel Roll Forming Machine

-

PU Roof:Wall Panel Roll Forming Machine

-

Standing Beam Roll Forming Machine

-

Ridge Cap Roll Forming Machine

-

Down Spout Roll Forming Machine

-

Gutter Roll Forming Machine

-

Roof Panel roll forming Machine

-

Cable Tray Roll Forming Machine

- -

CZ Purlin Roll Forming Machine

- -

Vineyard Post Roll Forming Machine

- -

Stud and Track Roll Forming Machine

- -

Roller Shutter Door Roll Forming Machine

- -

Fire Damper Roll Forming Machine

- -

Metal Slitting Line

- -

Cut to Length Line

- -

Tube mill

--

High Frequency Carbon Steel Tube Mill

-

DB25 High-frequency Tube Welding line

-

DB32 Welding Pipe Tube Mill

-

DB50 Carbon Steel Tube Mill Line

-

DB50 Expanded 76 High Frequency Welded Tube Mill Line

-

DB76 Expanded 127 HF Straight Seam Welded Tube Mill Line

-

DB89 Welded Pipe Forming Tube Mill Machine

-

DB114 Welded Carbon Steel Tube Mill

-

DB219 ERW Welded Tube Mill

-

High Frequency Carbon Steel Tube Mill

-

PU Sandwich Panel Line

- -

Auxiliary Machine

-

Product description

Parameters

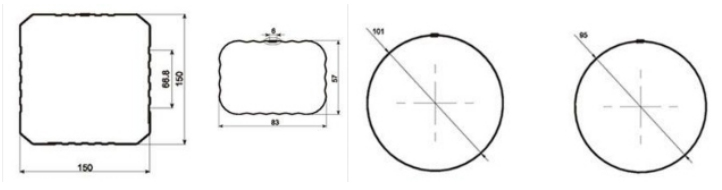

Profile drawings

Optional configuration

Video

Description

Dingbo downspout roll forming machine is used in rainwater goods system. Machineable thickness of downspout and gutter could be 0.4mm-0.8mm, 0.8-1.5mm or as you requested with raw material: Aluminum, Galvanized steel, Painted steel, Galvalume, Stainless steel,etc.

There are square pipe roll forming machine (rectangular downspouts roll forming machine) and round pipe roll forming machine (round corrugated downspouts roll forming machine) also a separate elbow machine. Machineable size depends on your profile drawing.

In rainwater goods system, we are able to manufacture more machines like gutter roll forming machine, etc.

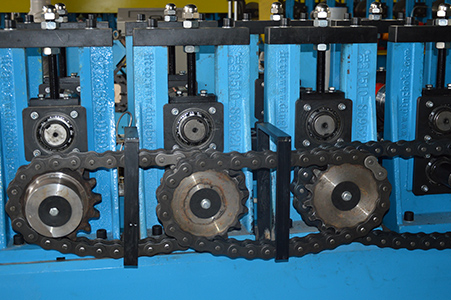

Our downspout roll forming machine mainly consists of uncoiler, roll forming system, cutting equipment, hydraulic system, control system and out table. It can make curve for down pipe to meet the requirement of practical engineering projects.

Version to design

Working Flow

Decoiler -- Feeding -- Roll forming -- Hydraulic cutter -- Output table

Machine pictures

Application pictures

Downspouts mainly collect roof rain water, which is part of the downspouts system, and concentrate on the rainwater pipes laid below the ground.

A rain gutter or down spout is a narrow channel, or trough, forming the component of a roof system which collects and diverts rainwater shed by the roof. Down spout roll forming machine is the essential for its production.

The Downspout roll forming machine is the role of the downspout product of roofing rainwater collected, and then the rain can after downspout machine production of downspout usually flows into the underground pipeline, such a process is done simply for water treatment, visible downspout work is very simple.

Previous

Gutter Roll Forming Machine