PRODUCTS

Products

-

Guardrail Roll Forming Machine

- -

Rack Shelf Roll Forming Machine

- -

Strut Channel Roll Forming Machine

- -

Scaffolding Roll Forming Machine

- -

Customized Roll Forming Machine

- -

Door Frame Roll Forming Machine

- -

Deck Floor Roll Forming Machine

- -

Roof Panel Roll Forming machine

--

Roof Panel roll forming Machine

-

Corrugated Roll Forming Machine

-

Glazed Tile Roll Forming Machine

-

Double Layer Roof Panel Roll Forming Machine

-

PU Roof:Wall Panel Roll Forming Machine

-

Standing Beam Roll Forming Machine

-

Ridge Cap Roll Forming Machine

-

Down Spout Roll Forming Machine

-

Gutter Roll Forming Machine

-

Roof Panel roll forming Machine

-

Cable Tray Roll Forming Machine

- -

CZ Purlin Roll Forming Machine

- -

Vineyard Post Roll Forming Machine

- -

Stud and Track Roll Forming Machine

- -

Roller Shutter Door Roll Forming Machine

- -

Fire Damper Roll Forming Machine

- -

Metal Slitting Line

- -

Cut to Length Line

- -

Tube mill

--

High Frequency Carbon Steel Tube Mill

-

DB25 High-frequency Tube Welding line

-

DB32 Welding Pipe Tube Mill

-

DB50 Carbon Steel Tube Mill Line

-

DB50 Expanded 76 High Frequency Welded Tube Mill Line

-

DB76 Expanded 127 HF Straight Seam Welded Tube Mill Line

-

DB89 Welded Pipe Forming Tube Mill Machine

-

DB114 Welded Carbon Steel Tube Mill

-

DB219 ERW Welded Tube Mill

-

High Frequency Carbon Steel Tube Mill

-

PU Sandwich Panel Line

- -

Auxiliary Machine

-

Product description

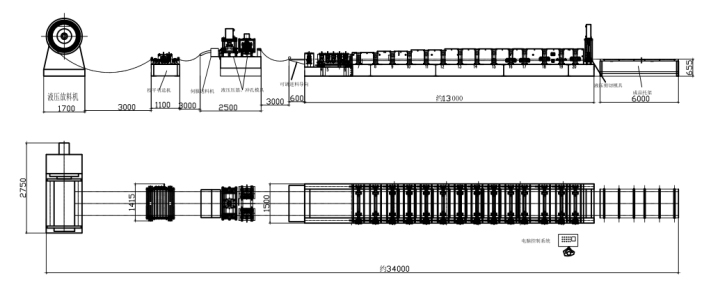

Parameters

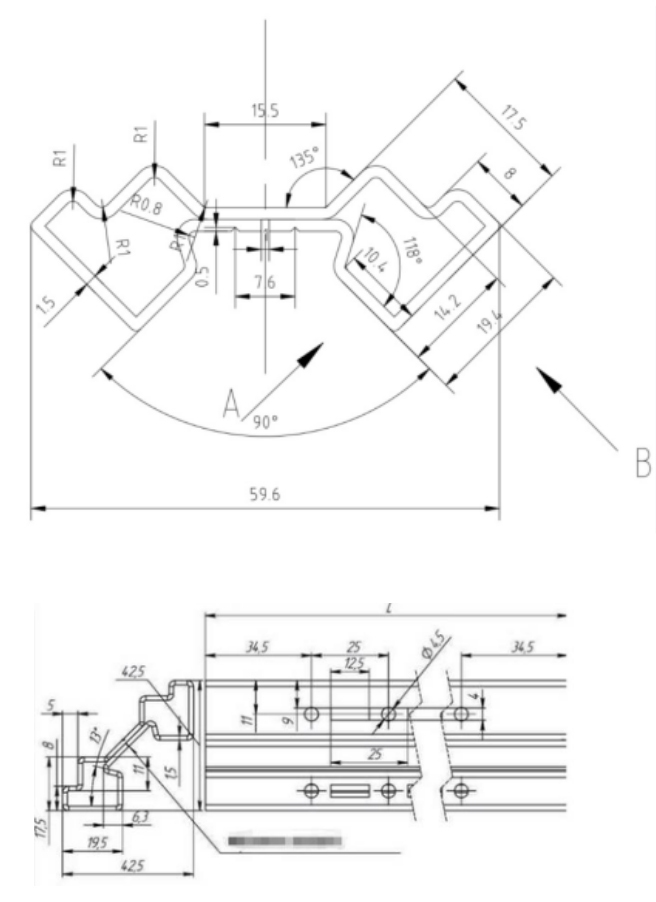

Profile drawings

Optional configuration

Video

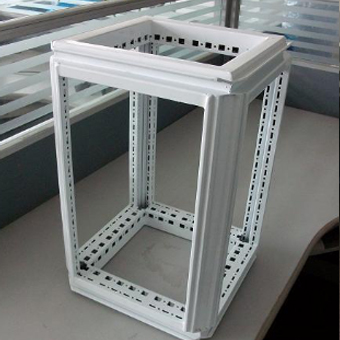

Description

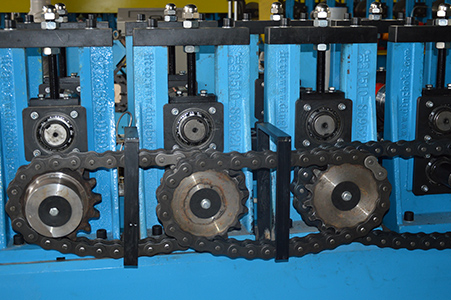

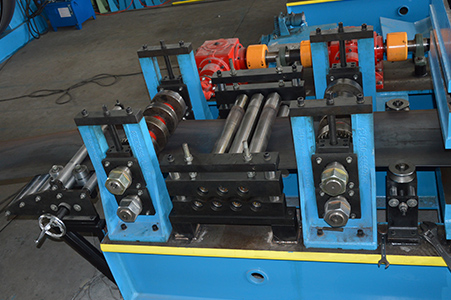

Automaitc electric factory using cabinet frame roll forming machine with welding for electric cabinet rack, electronic box pole, metal case frame which using in switchgear system, low voltage panel building, control cabinetelectrical instruments etc.

Working Flow

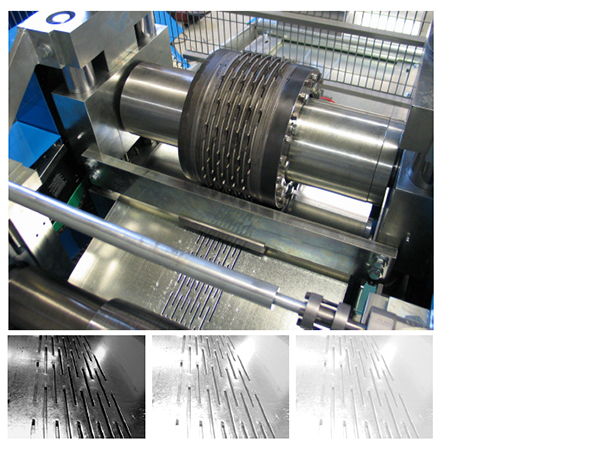

Uncoiler -- Servo Feeding -- Punching -- roll forming machine -- Roller welding -- Saw cutting -- finished product output table

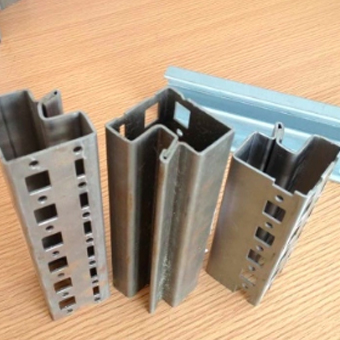

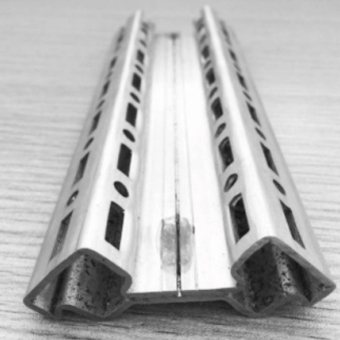

Profiles pictures

|

|

|

|

Application

Electrical cabinet frame. It is a column. The beam is provided with at least one sealing groove. The angular connector is designed in a three-dimensional coordinate shape. The groove is matched with the column and the sealing groove on the beam. The advantages are increased structural strength and improved cabinet protection. , Thereby improving the replacement of electrical products and the safety of operators.

|

|

|

|

Previous

Steel Silo Roll Forming Machine

Next

None