PRODUCTS

Products

-

Guardrail Roll Forming Machine

- -

Rack Shelf Roll Forming Machine

- -

Strut Channel Roll Forming Machine

- -

Scaffolding Roll Forming Machine

- -

Customized Roll Forming Machine

- -

Door Frame Roll Forming Machine

- -

Deck Floor Roll Forming Machine

- -

Roof Panel Roll Forming machine

--

Roof Panel roll forming Machine

-

Corrugated Roll Forming Machine

-

Glazed Tile Roll Forming Machine

-

Double Layer Roof Panel Roll Forming Machine

-

PU Roof:Wall Panel Roll Forming Machine

-

Standing Beam Roll Forming Machine

-

Ridge Cap Roll Forming Machine

-

Down Spout Roll Forming Machine

-

Gutter Roll Forming Machine

-

Roof Panel roll forming Machine

-

Cable Tray Roll Forming Machine

- -

CZ Purlin Roll Forming Machine

- -

Vineyard Post Roll Forming Machine

- -

Stud and Track Roll Forming Machine

- -

Roller Shutter Door Roll Forming Machine

- -

Fire Damper Roll Forming Machine

- -

Metal Slitting Line

- -

Cut to Length Line

- -

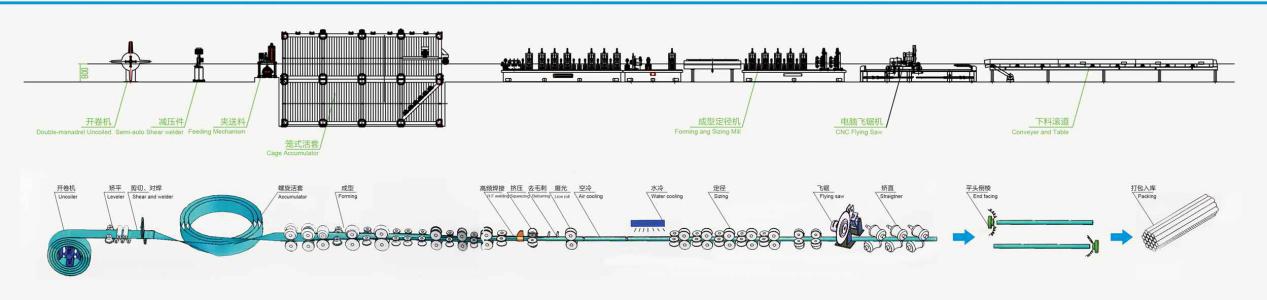

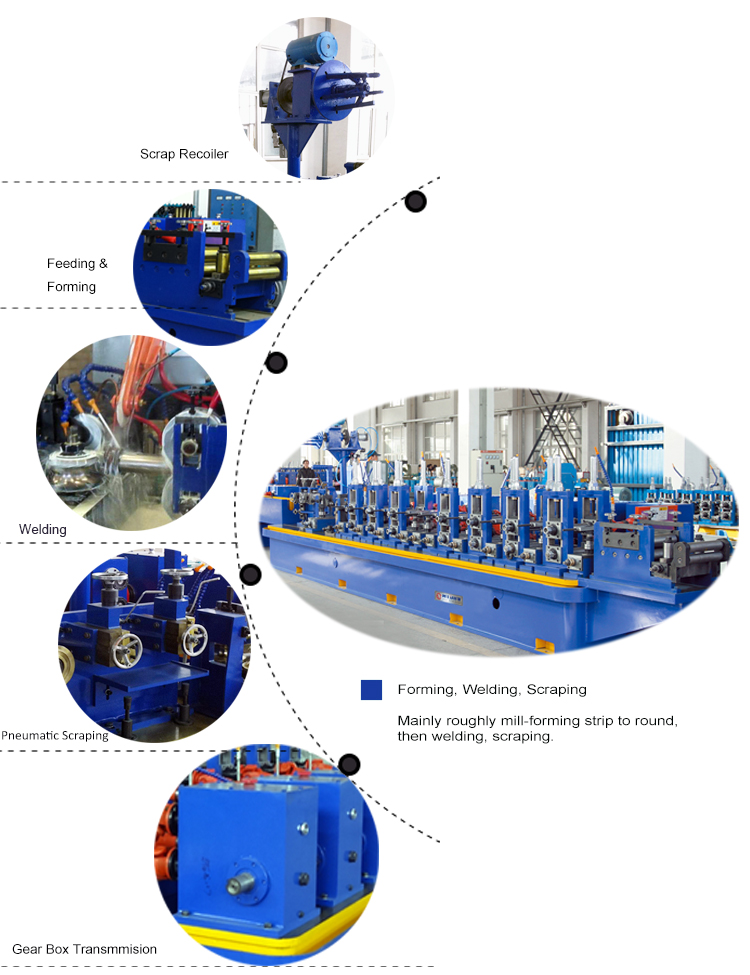

Tube mill

--

High Frequency Carbon Steel Tube Mill

-

DB25 High-frequency Tube Welding line

-

DB32 Welding Pipe Tube Mill

-

DB50 Carbon Steel Tube Mill Line

-

DB50 Expanded 76 High Frequency Welded Tube Mill Line

-

DB76 Expanded 127 HF Straight Seam Welded Tube Mill Line

-

DB89 Welded Pipe Forming Tube Mill Machine

-

DB114 Welded Carbon Steel Tube Mill

-

DB219 ERW Welded Tube Mill

-

High Frequency Carbon Steel Tube Mill

-

PU Sandwich Panel Line

- -

Auxiliary Machine

-

Product Descriptions

Optional Models:

|

Model |

Diameter of Welded Tubes |

Wall Thickness of Round Tube |

Max. Size of Square Tube |

Max. Size of Rec. Tube |

Wall Thickness of Sq & Rec Tube |

Speed of Tube Welding |

Power of Major Motor |

High Frequency Power |

|

DB16 |

8-25mm |

0.3-1.0mm |

20x20mm |

12.7x25.4mm |

0.3-0.8mm |

30-110m/min |

37KW |

100KW |

|

DB25 |

8-32mm |

0.4-1.3mm |

25x25mm |

20x30mm |

0.4-1.0mm |

30-110m/min |

45KW |

100KW |

|

DB32 |

10-40mm |

0.5-1.8mm |

30x30mm |

20x40mm |

0.5-1.4mm |

30-100m/min |

90KW |

150KW |

|

DB45 |

13-50.8mm |

0.6-2.3mm |

40x40mm |

30x50mm |

0.6-1.7mm |

30-100m/min |

110KW |

150KW |

|

DB50 |

19-63.5mm |

0.7-2.75mm |

50x50mm |

40x60mm |

0.7-2.2mm |

30-100m/min |

160KW |

200KW |

|

DB50 to 76 |

19-76mm |

0.7-2.75mm |

60x60mm |

40x80mm |

0.7-2.2mm |

30-100m/min |

160KW |

200KW |

|

DB60 |

19-63.5mm |

0.8-3.5mm |

50x50mm |

40x60mm |

0.8-2.7mm |

30-90m/min |

185KW |

250KW |

|

DB60 to 76 |

19-76mm |

0.8-3.5mm |

60x60mm |

40x80mm |

0.8-2.7mm |

30-90m/min |

200KW |

250KW |

|

DB60 to 100 |

22-100mm |

1.0-3.0mm |

76.2x76.2mm |

50.8x101.6mm |

1.0-2.5mm |

30-80m/min |

200KW |

250KW |

|

DB76 |

25-90mm |

1.0-4.0mm |

70x70mm |

60x80mm |

1.0-3.2mm |

30-70m/min |

110KWx2 |

300KW |

|

DB76 to 127 |

32-127mm |

1.2-4.0mm |

100x100mm |

80x120mm |

1.2-3.0mm |

30-70m/min |

110KWx2 |

300KW |

|

DB90 |

32-127mm |

1.5-4.5mm |

100x100mm |

80x120mm |

1.5-3.5mm |

20-60m/min |

132KWx2 |

400KW |

|

DB90 to 140 |

32-140mm |

1.5-4.5mm |

110x110mm |

100x120mm |

1.5-3.5mm |

20-60m/min |

132KWx2 |

400KW |

|

DB115 |

48-127mm |

1.5-5.0mm |

100x100mm |

80x120mm |

1.5-4.0mm |

20-60m/min |

160KWx2 |

400KW |

|

DB115 to 140 |

48-140mm |

1.5-5.0mm |

110x110mm |

100x120mm |

1.5-4.0mm |

20-60m/min |

160KWx2 |

400KW |

|

DB115 to 165 |

48-165mm |

1.8-5.0mm |

130x130mm |

120x140mm |

1.8-4.0mm |

20-60m/min |

160KWx2 |

400KW |

|

DB165 |

50.8-165mm |

2.0-6.0mm |

130x130mm |

120x140mm |

2.0-5.0mm |

15-50m/min |

200KWx2 |

500KW |

|

DB165 to 219 |

76-219mm |

2.0-6.0mm |

170x170mm |

140x200mm |

2.0-5.0mm |

15-45m/min |

200KWx2 |

500KW |

|

DB219 |

89-219mm |

2.5-8.0mm |

170x170mm |

140x200mm |

2.5-6.0mm |

12-35/min |

220KWx2 |

600KW |

|

DB273 |

102-273mm |

2.5-10.0mm |

210x210mm |

180x240mm |

2.5-8.0mm |

10-30m/min |

250KWx2 |

800KW |

|

DB355 |

219-355mm |

4.0-12.0mm |

280x280mm |

260x300mm |

4.0-10.0mm |

10-30m/min |

250KWx2 |

1200KW |

Machine pic

Application