PRODUCTS

Products

-

Guardrail Roll Forming Machine

- -

Rack Shelf Roll Forming Machine

- -

Strut Channel Roll Forming Machine

- -

Scaffolding Roll Forming Machine

- -

Customized Roll Forming Machine

- -

Door Frame Roll Forming Machine

- -

Deck Floor Roll Forming Machine

- -

Roof Panel Roll Forming machine

--

Roof Panel roll forming Machine

-

Corrugated Roll Forming Machine

-

Glazed Tile Roll Forming Machine

-

Double Layer Roof Panel Roll Forming Machine

-

PU Roof:Wall Panel Roll Forming Machine

-

Standing Beam Roll Forming Machine

-

Ridge Cap Roll Forming Machine

-

Down Spout Roll Forming Machine

-

Gutter Roll Forming Machine

-

Roof Panel roll forming Machine

-

Cable Tray Roll Forming Machine

- -

CZ Purlin Roll Forming Machine

- -

Vineyard Post Roll Forming Machine

- -

Stud and Track Roll Forming Machine

- -

Roller Shutter Door Roll Forming Machine

- -

Fire Damper Roll Forming Machine

- -

Metal Slitting Line

- -

Cut to Length Line

- -

Tube mill

--

High Frequency Carbon Steel Tube Mill

-

DB25 High-frequency Tube Welding line

-

DB32 Welding Pipe Tube Mill

-

DB50 Carbon Steel Tube Mill Line

-

DB50 Expanded 76 High Frequency Welded Tube Mill Line

-

DB76 Expanded 127 HF Straight Seam Welded Tube Mill Line

-

DB89 Welded Pipe Forming Tube Mill Machine

-

DB114 Welded Carbon Steel Tube Mill

-

DB219 ERW Welded Tube Mill

-

High Frequency Carbon Steel Tube Mill

-

PU Sandwich Panel Line

- -

Auxiliary Machine

-

Product description

Parameters

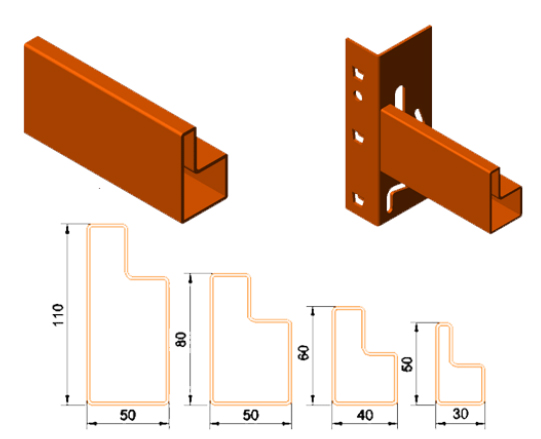

Profile drawings

Optional configuration

Video

Description

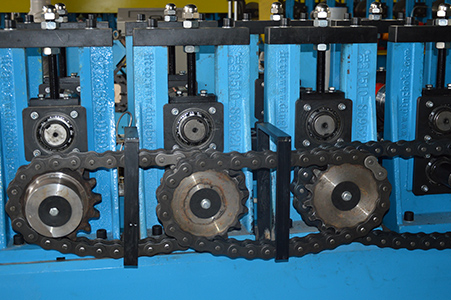

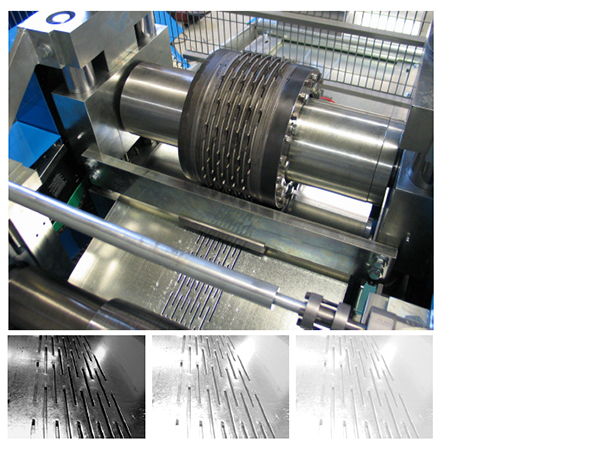

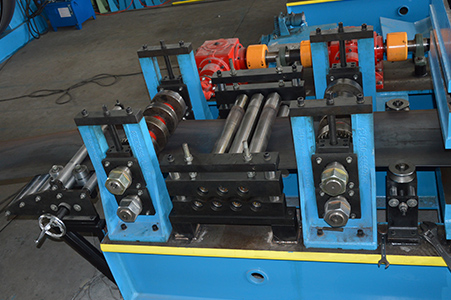

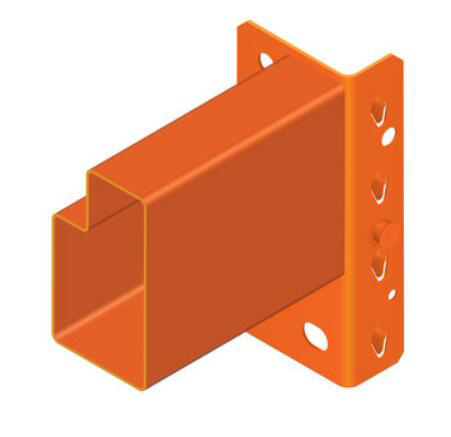

Pallet racking roll forming machine is widely used in producing upright frame, box beam and step beam. Our intelligent roll forming machine could make wide range of step beam size with manually adjust sizes. Material thickness is from 1.5-3mm with raw material Cold-rolled Steel,Carbon steel. the speed is about 10-20m/min.This machine is widely used in high warehouses.

In warehouse pallet racking system, we are able to manufacture more machines like upright section roll forming machine and shelf panel roll forming machine etc.

We make different solutions according to customers’ drawing, tolerance and budget, offering professional one-to-one service, adaptable for your every need. Whichever line you choose, the quality of Dingbo Technology will ensure you obtain perfectly functional profiles.

Working flow:

Uncoiler——Leveler & feeding--Roll Forming—High Frequency Welder/Argon arc welding--Flying Saw Cutting—Output table

Q&A

1.Q: What kinds of experience do you have in producing pallet rack roll forming machine?

A: We have exported pallet rack production line to Saudi Arabia, Mexico, Peru, Egypt, etc. In warehouse pallet racking system, we are able to manufacture Upright beam roll forming machine, Box beam roll forming machine, step beam roll forming machine and shelf panel roll forming machine etc. We are confident to solve your shelves problem.

2.Q: How many sizes can produce this machine?

A: We adopt cast iron structure or cantilever structure with automatic width-change and height-change system. One machine could produce several profiles, we would check your profile drawings to meet your needs. We are dedicated to provide cost-effective solutions.

3.Q: What is delivery time of step beam roll forming machine?

A: 80 days to 100 days depends on your drawing.

4.Q: What is your machine speed?

A: Machine’s working speed depends on drawing specially punch drawing. Normally forming speed is around 20m/min, Because it’s normally with high frequency welder to make sure the continuous welding.

5.Q: How could you control your machine’s precision and quality

A: Our secret to producing such precision is that our factory has its own production line, from punching molds to forming rollers, each mechanical part is completed independently by our factory self. We strictly control the accuracy at each step from design, processing, assembling to quality control, we refuse to cut corners.

6.Q: What is your after-sales service system?

A: We don’t hesitate to give you a two-years warranty period for whole lines, five years for motor: If there will be any quality problems caused by non-human factors, we will handle it immediately for you and we will be ready for you 7X24H. One purchase, lifetime care for you.