PRODUCTS

Products

-

Guardrail Roll Forming Machine

- -

Rack Shelf Roll Forming Machine

- -

Strut Channel Roll Forming Machine

- -

Scaffolding Roll Forming Machine

- -

Customized Roll Forming Machine

- -

Door Frame Roll Forming Machine

- -

Deck Floor Roll Forming Machine

- -

Roof Panel Roll Forming machine

--

Roof Panel roll forming Machine

-

Corrugated Roll Forming Machine

-

Glazed Tile Roll Forming Machine

-

Double Layer Roof Panel Roll Forming Machine

-

PU Roof:Wall Panel Roll Forming Machine

-

Standing Beam Roll Forming Machine

-

Ridge Cap Roll Forming Machine

-

Down Spout Roll Forming Machine

-

Gutter Roll Forming Machine

-

Roof Panel roll forming Machine

-

Cable Tray Roll Forming Machine

- -

CZ Purlin Roll Forming Machine

- -

Vineyard Post Roll Forming Machine

- -

Stud and Track Roll Forming Machine

- -

Roller Shutter Door Roll Forming Machine

- -

Fire Damper Roll Forming Machine

- -

Metal Slitting Line

- -

Cut to Length Line

- -

Tube mill

--

High Frequency Carbon Steel Tube Mill

-

DB25 High-frequency Tube Welding line

-

DB32 Welding Pipe Tube Mill

-

DB50 Carbon Steel Tube Mill Line

-

DB50 Expanded 76 High Frequency Welded Tube Mill Line

-

DB76 Expanded 127 HF Straight Seam Welded Tube Mill Line

-

DB89 Welded Pipe Forming Tube Mill Machine

-

DB114 Welded Carbon Steel Tube Mill

-

DB219 ERW Welded Tube Mill

-

High Frequency Carbon Steel Tube Mill

-

PU Sandwich Panel Line

- -

Auxiliary Machine

-

Product Descriptions

- High level of automation, easy to operate and maintain.

- Hydraulic Decoiler with a loading car for quick loading

- Leveler with 4 high and 6 high rollers for the maximum flatness

- Gentle treatment of surfaces by high-quality rollers and conveyor materials

- High-quality cuts with minimum burr

- Compact design requires minimum space

- Low cost, high quality, optimum productivity

Technical Parameters

|

Items |

Main specification |

|

Material |

PPGI, GI, Aluminum, Carbon steel, Hot Rolled, Cold Rolled, Stainless steel |

|

Processing Thickness |

0.3-2mm |

|

Processing Width |

1250mm |

|

Slitting Accuracy |

±0.05 mm |

|

Slitting Speed |

0-30m/min |

|

Coil Inner Diameter |

480-520mm |

|

Coil Outer Diameter |

≤1400 mm |

|

Max. Slitting Numbers |

5-10pcs |

|

Slitting Coil Width |

≥20 mm |

|

Not limited to these parameters, custom made according to client practical demands. |

|

Main Components

|

Name |

Quantity |

|

Hydraulic decoiler with car |

1 set |

|

Leveler |

1 set |

|

Feeding |

1 set |

|

Slitting machine |

1 set |

|

Scrap winder |

1 set |

|

Damper |

1 set |

|

Hydraulic recoiler with coil car |

1 set |

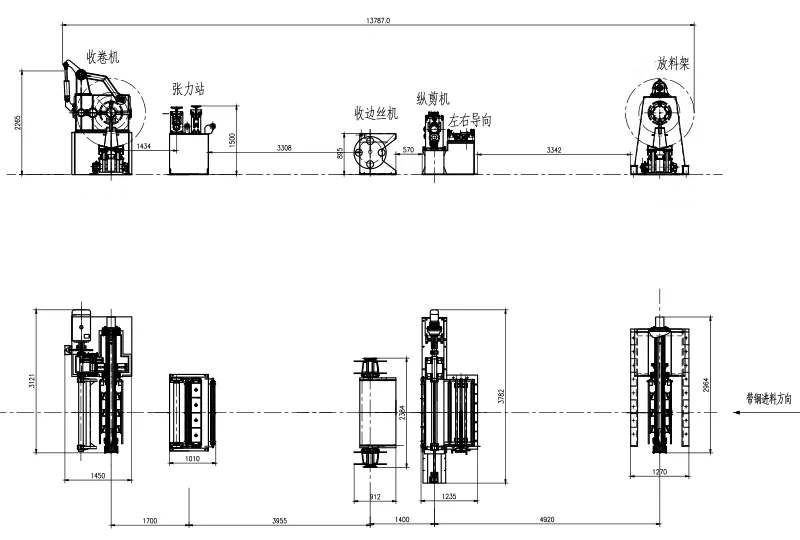

Machine pictures

|

|