PRODUCTS

Products

-

Guardrail Roll Forming Machine

- -

Rack Shelf Roll Forming Machine

- -

Strut Channel Roll Forming Machine

- -

Scaffolding Roll Forming Machine

- -

Customized Roll Forming Machine

- -

Door Frame Roll Forming Machine

- -

Deck Floor Roll Forming Machine

- -

Roof Panel Roll Forming machine

--

Roof Panel roll forming Machine

-

Corrugated Roll Forming Machine

-

Glazed Tile Roll Forming Machine

-

Double Layer Roof Panel Roll Forming Machine

-

PU Roof:Wall Panel Roll Forming Machine

-

Standing Beam Roll Forming Machine

-

Ridge Cap Roll Forming Machine

-

Down Spout Roll Forming Machine

-

Gutter Roll Forming Machine

-

Roof Panel roll forming Machine

-

Cable Tray Roll Forming Machine

- -

CZ Purlin Roll Forming Machine

- -

Vineyard Post Roll Forming Machine

- -

Stud and Track Roll Forming Machine

- -

Roller Shutter Door Roll Forming Machine

- -

Fire Damper Roll Forming Machine

- -

Metal Slitting Line

- -

Cut to Length Line

- -

Tube mill

--

High Frequency Carbon Steel Tube Mill

-

DB25 High-frequency Tube Welding line

-

DB32 Welding Pipe Tube Mill

-

DB50 Carbon Steel Tube Mill Line

-

DB50 Expanded 76 High Frequency Welded Tube Mill Line

-

DB76 Expanded 127 HF Straight Seam Welded Tube Mill Line

-

DB89 Welded Pipe Forming Tube Mill Machine

-

DB114 Welded Carbon Steel Tube Mill

-

DB219 ERW Welded Tube Mill

-

High Frequency Carbon Steel Tube Mill

-

PU Sandwich Panel Line

- -

Auxiliary Machine

-

Product description

Parameters

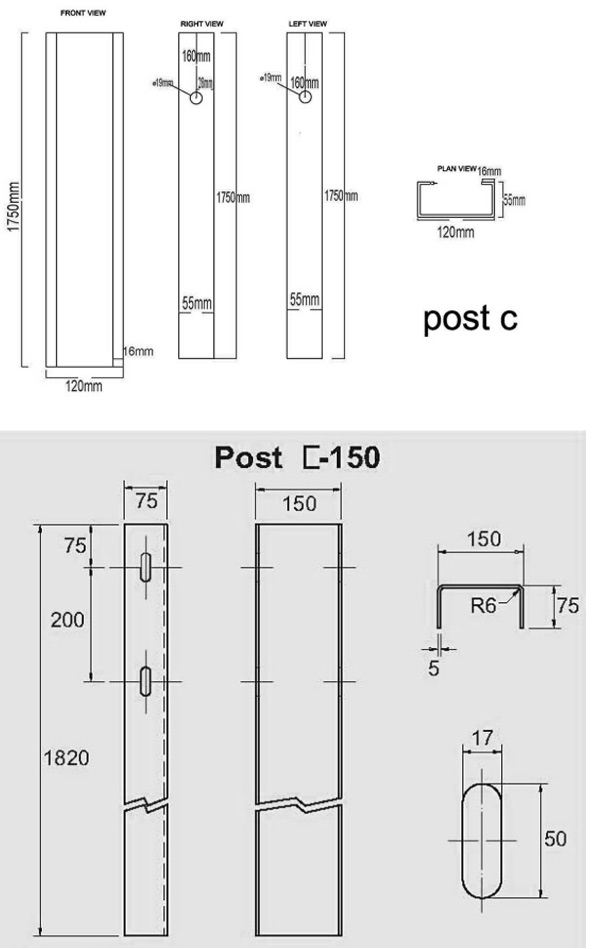

Profile drawings

Optional configuration

Video

Description

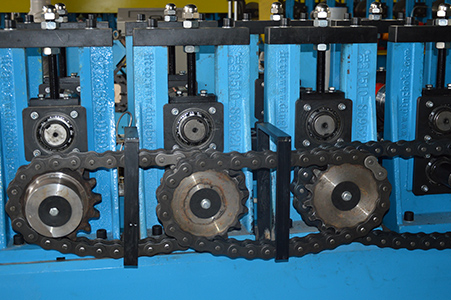

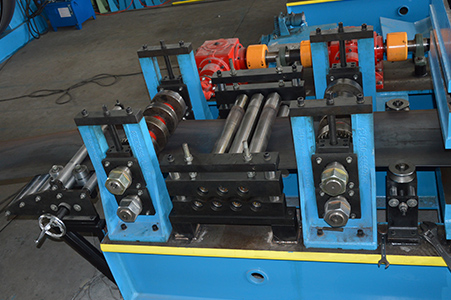

Steel C / U post is common in Mexico, Uruguay, Bolivia, Chile, etc. This C/U Post Roll Forming Machine can be designed for thickness 4-6mm, it is widely used as post of guardrail. We use forged iron stands(see picture) and gearbox driving to make sure this machine can work long in a stable situation.

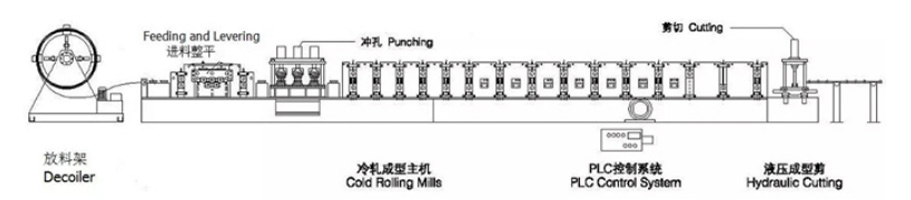

Technological process

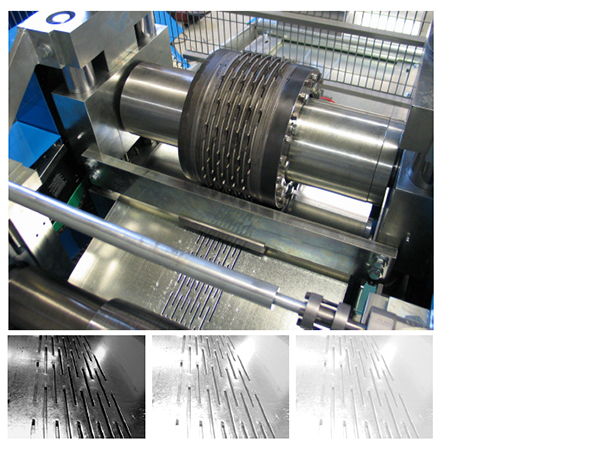

Decoiler—Feeding&Leveling—Punching—Roll forming—Hydraulic cutting—Output tables

Technical specification

Parameters:

1.Suitable Material: Hot Rolled Steel

2.Material Thickness: 4 – 5 mm

3.Line speed: 0-8 m / min

Components:

The C/U Post Highway Guardrail Roll Forming Machine is mainly made up of the following parts.

1.Un-coiler(Manual/Hydraulic)

2.Feeding and straightening device

3.Hydraulic punching

4.Roll forming unit

5.Hydraulic cutting device

6.PLC control box with touch screen

7.Receiving table

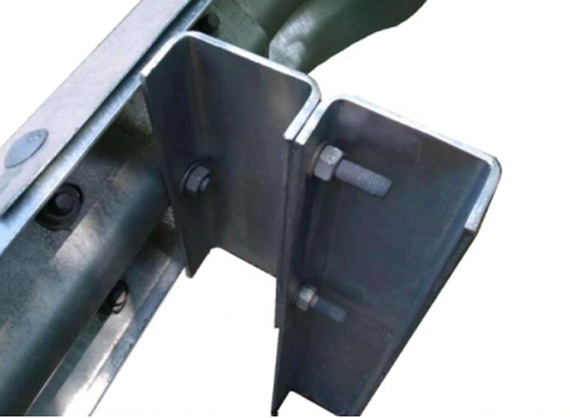

The sigma post as a support for the crash barrier and usually determines the performance of the guardrail during the collision. Proper installation of the sigma post will maximize the performance of the guardrail. The guardrail post has a long service life and the surface is usually hot-dip galvanized or spray-coated to provide rust and corrosion resistance.

Choosing the right guardrail post will have a strong ability to absorb collision energy of motorway barriers, and can be coordinated with the road line shape and various facilities. The sigma post can be installed and used on a small radius curve in motorway barriers, the connection is simple and convenient, and the damage is easy to replace.

Application

The C barrier post or U post as a support for the beam guardrail and usually determines the performance of the guardrail during the collision. Proper installation of the guardrail post will maximize the performance of the guardrail. The barrier post has a long service life and the surface is usually hot-dip galvanized or spray-coated to provide rust and corrosion resistance.

The steel C post both with and without flanges, which are differentiated according to your intended application. Usually, the pillars without flanges are mostly fixed to the soft soil by the pillars. But if you want to fix it on a concrete pavement, the pillar with steel plate is the best choice for your installation: just use long bolts to secure the pillar to the position you want.

|

|