PRODUCTS

Products

-

Guardrail Roll Forming Machine

- -

Rack Shelf Roll Forming Machine

- -

Strut Channel Roll Forming Machine

- -

Scaffolding Roll Forming Machine

- -

Customized Roll Forming Machine

- -

Door Frame Roll Forming Machine

- -

Deck Floor Roll Forming Machine

- -

Roof Panel Roll Forming machine

--

Roof Panel roll forming Machine

-

Corrugated Roll Forming Machine

-

Glazed Tile Roll Forming Machine

-

Double Layer Roof Panel Roll Forming Machine

-

PU Roof:Wall Panel Roll Forming Machine

-

Standing Beam Roll Forming Machine

-

Ridge Cap Roll Forming Machine

-

Down Spout Roll Forming Machine

-

Gutter Roll Forming Machine

-

Roof Panel roll forming Machine

-

Cable Tray Roll Forming Machine

- -

CZ Purlin Roll Forming Machine

- -

Vineyard Post Roll Forming Machine

- -

Stud and Track Roll Forming Machine

- -

Roller Shutter Door Roll Forming Machine

- -

Fire Damper Roll Forming Machine

- -

Metal Slitting Line

- -

Cut to Length Line

- -

Tube mill

--

High Frequency Carbon Steel Tube Mill

-

DB25 High-frequency Tube Welding line

-

DB32 Welding Pipe Tube Mill

-

DB50 Carbon Steel Tube Mill Line

-

DB50 Expanded 76 High Frequency Welded Tube Mill Line

-

DB76 Expanded 127 HF Straight Seam Welded Tube Mill Line

-

DB89 Welded Pipe Forming Tube Mill Machine

-

DB114 Welded Carbon Steel Tube Mill

-

DB219 ERW Welded Tube Mill

-

High Frequency Carbon Steel Tube Mill

-

PU Sandwich Panel Line

- -

Auxiliary Machine

-

Product Descriptions

Technical Parameters

|

Item |

Patameter |

|

Material |

Hot/cold rolled carbon steel or Galvanized steel coil |

|

Width of strip steel |

25-100mm |

|

Diameter |

8-25mm |

|

Square pipe |

10*10-25*25 |

|

Thickness of strip steel |

0.2-1.3mm |

|

Cutting Type |

Hot friction saw |

|

Cutting tolerance |

±1mm |

|

Tracking motor |

11Kw |

|

Pneumatic system |

0.4-0.7Mpa |

|

Unit power standard |

380V / 22V; 50HZ; three-phase four-wire system |

|

|

Unit power |

high frequency |

100 KW |

|

Main motor |

40 KW |

|

|

Unit area |

30M×5M(L*W) |

|

|

High-frequency room volume |

4M×4M×2.8M |

|

|

Water source |

cooling pool 30m³ / 1 set high-pressure pump |

|

|

Air source |

1 set Air compressor |

|

|

Required lifting equipment |

Two 10-ton cranes |

|

|

Conventional consumables |

|

|

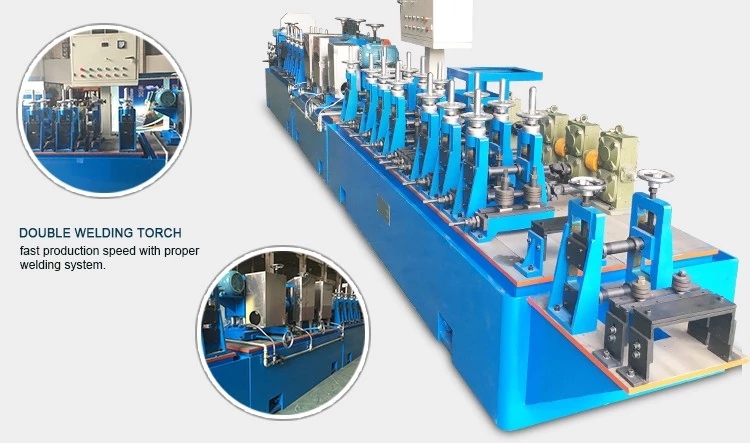

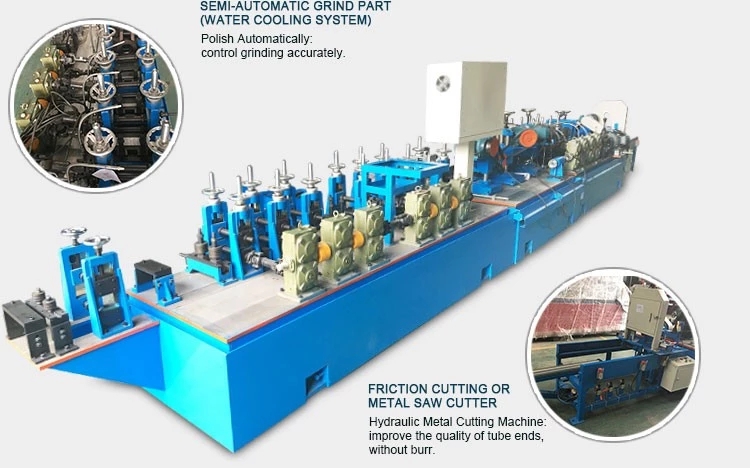

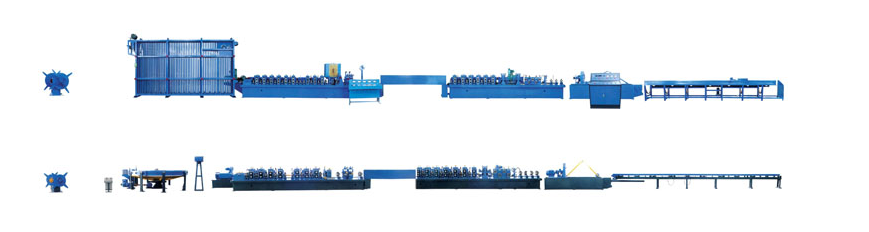

Machine pictures