PRODUCTS

Products

-

Guardrail Roll Forming Machine

- -

Rack Shelf Roll Forming Machine

- -

Strut Channel Roll Forming Machine

- -

Scaffolding Roll Forming Machine

- -

Customized Roll Forming Machine

- -

Door Frame Roll Forming Machine

- -

Deck Floor Roll Forming Machine

- -

Roof Panel Roll Forming machine

--

Roof Panel roll forming Machine

-

Corrugated Roll Forming Machine

-

Glazed Tile Roll Forming Machine

-

Double Layer Roof Panel Roll Forming Machine

-

PU Roof:Wall Panel Roll Forming Machine

-

Standing Beam Roll Forming Machine

-

Ridge Cap Roll Forming Machine

-

Down Spout Roll Forming Machine

-

Gutter Roll Forming Machine

-

Roof Panel roll forming Machine

-

Cable Tray Roll Forming Machine

- -

CZ Purlin Roll Forming Machine

- -

Vineyard Post Roll Forming Machine

- -

Stud and Track Roll Forming Machine

- -

Roller Shutter Door Roll Forming Machine

- -

Fire Damper Roll Forming Machine

- -

Metal Slitting Line

- -

Cut to Length Line

- -

Tube mill

--

High Frequency Carbon Steel Tube Mill

-

DB25 High-frequency Tube Welding line

-

DB32 Welding Pipe Tube Mill

-

DB50 Carbon Steel Tube Mill Line

-

DB50 Expanded 76 High Frequency Welded Tube Mill Line

-

DB76 Expanded 127 HF Straight Seam Welded Tube Mill Line

-

DB89 Welded Pipe Forming Tube Mill Machine

-

DB114 Welded Carbon Steel Tube Mill

-

DB219 ERW Welded Tube Mill

-

High Frequency Carbon Steel Tube Mill

-

PU Sandwich Panel Line

- -

Auxiliary Machine

-

Product description

Parameters

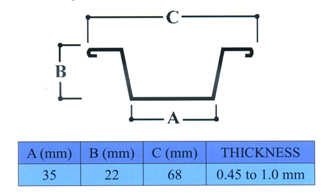

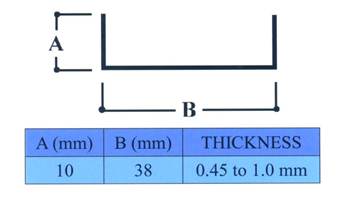

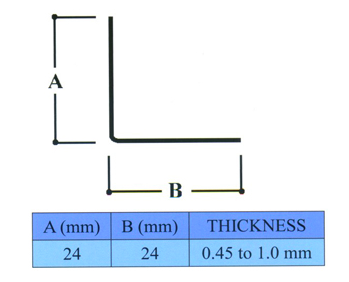

Profile drawings

Optional configuration

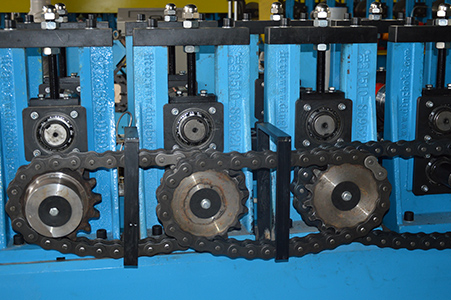

Video

Description

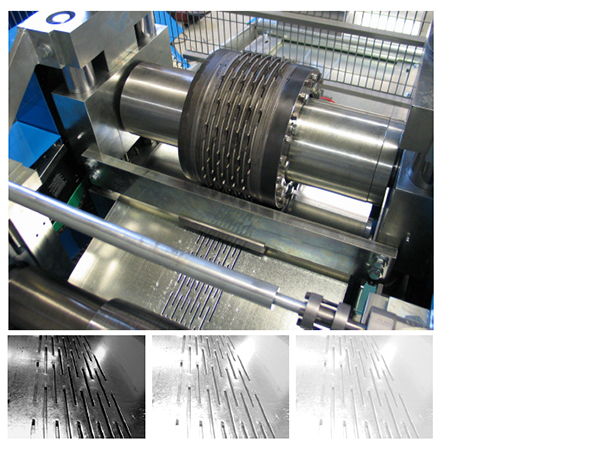

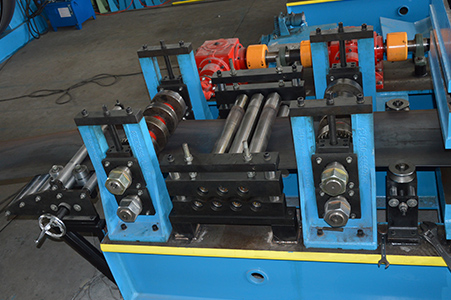

Furring Channel roll forming machine can produce furring channel which use with main channel and wall angle together. Normal material thickness is 0.4-1mm, and normal speed is 10-15m/min, also can design for 40-60m/min with flying cutting depends on your production requirement.

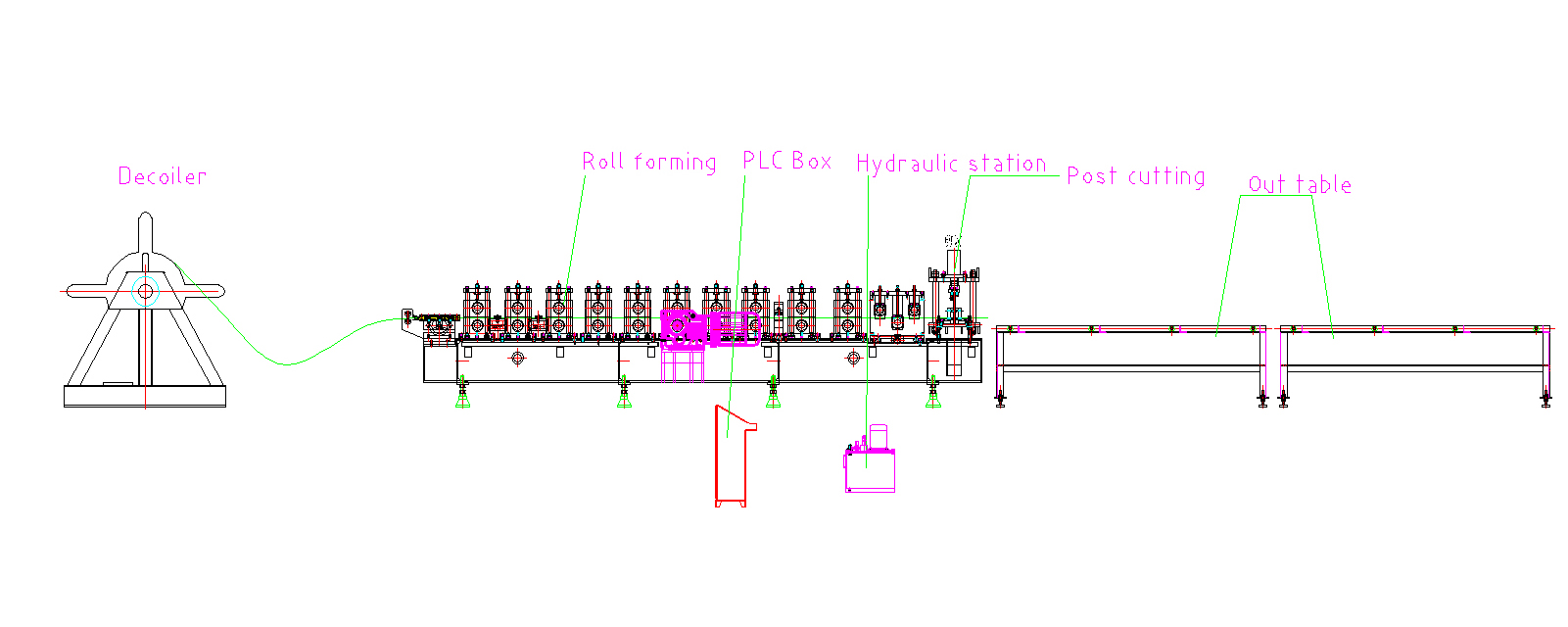

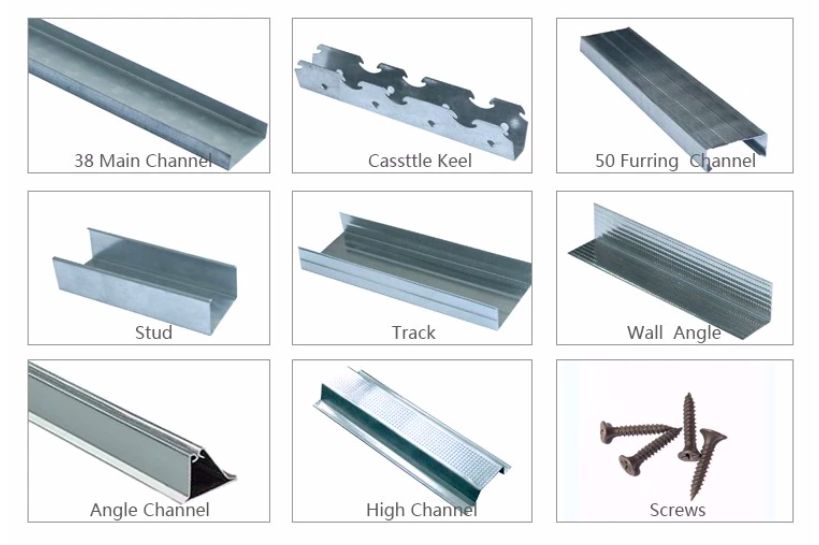

Drywall Roll Forming Machine include stud and track Roll Forming Machine, Main Channel Roll Forming Machine, Omega Furring Channel Roll Forming Machine, Wall angle Roll Forming Machine, Ceiling Roll Forming Machine,Light Steel Keel Roll Forming Machine etc.

Dingbo drywall roll forming machine will be your best choice. We can customize as per your profile drawing.

Working Flow

Uncoiler --Roll-forming -- Hydraulic cutting -- Output table

Application

Furring channel is a main material made of light steel and used for ceilings.

It is connected to the floor by screws and is used to fix ceilings or objects.

It is used to decorate the exterior wall and the roof of the building, which is made of plaster board, decorative plasterboard, etc.

It is suitable for the decoration of the roof of various buildings, the inner and outer wall of the building and the basic material of the scaffold type ceiling.

The Furring ceiling system is a suspended steel framing system, clad with gypsum boards. Its grids are concealed behind the ceiling board. The finishing surface would be smooth and may receive direct decoration such as painting and pasing wall paper. It is mostly used in where plain ceiling is required.

|

|

Previous

None